A transmission line tower, also known as an electrical pylon, is a tall structure that supports an overhead power line. Typically, it is a steel lattice tower. Transmission towers in electrical grids carry high-voltage transmission lines that move bulk electric power from generating stations to electrical substations, where it is delivered to end users. Transmission towers fall into four categories: suspension towers,tension towers, dead-end terminal towers and transposition towers.

| Voltage | 10kV to 1100kV |

| Shape of steel | Angular / tubular steel |

| Lattice Type | 3/4 legs lattice |

| Tower Type | Suspension Tower, Tension Tower, Dead Tower, Substation Structure |

| Height | 10M-100M |

| Circuit | Single / Double Circuit |

| Material | 1.High strength low alloy structural steel: Q420B which is equivalent with ASTM Gr60 2.High strength low alloy structural steels: Q355B which is equivalent with ASTM Gr50 or S355JR 3.Carbon Structural Steel: Q235B which is equivalent with ASTM A36 or S235JR |

| Welding | AWS D1.1 |

| Surface treatment | Hot dip galvanizing /painting/Powder coating |

| Hot dip galvanization | GB/T 13912-2002, EN ISO 1461,ASTM/A123 or equivalent |

| Welding Standard | AWS D1.1, AS554, AS 4100 standard or equivalent |

| Earthquakeproof Grade | Grade 8 |

| Ice wrapping | 5-10 mm |

| Verticality | 1 / 1000 |

| Working Temperature | - 45°C -+ 45°C |

| Nuts& Bolts | Mainly ISO 898 grade 6.8 and 8.8 bolts for Both Chinese, ISO and DIN standard |

| Working lifespan | 30/50 years |

Our transmission towers can be made of angular steel, steel pipe or both. We design the towers to be high safety with high Material utilization so as yo control the cost. And the raw materials are from the trusted steel suppliers which we’ve been collaborating with for decades. In the stage of welding, CO₂ welding and submerged arc auto welding are adopted in our fabrication process. Both Factory test report and type test are available if required.

1. We use the latest software:PLS and MS Tower, STW, SAP2000, TWsolid, SLCAD, AutoCAD,

2. Design codes available:

1) Chinese National Standard:

a.For Tower and Pole Structures of Overhead Transmission Line: DL/T 5154-2002 Technical Regulation of Design

b. For foundation of Overhead Transmission Line: DL/T 5219-2005 Technical Regulation for Designing Foundation of Overhead Transmission Line

2)American Standard:

a. ASCE 10-97-2000 Design of Latticed Steel Transmission Structures

b. ACI 318-02 Building Code Requirement for Structure Concrete

3. We can offer required tower test: loading test, type test and others as per request and all tests are conducted by Government authority.

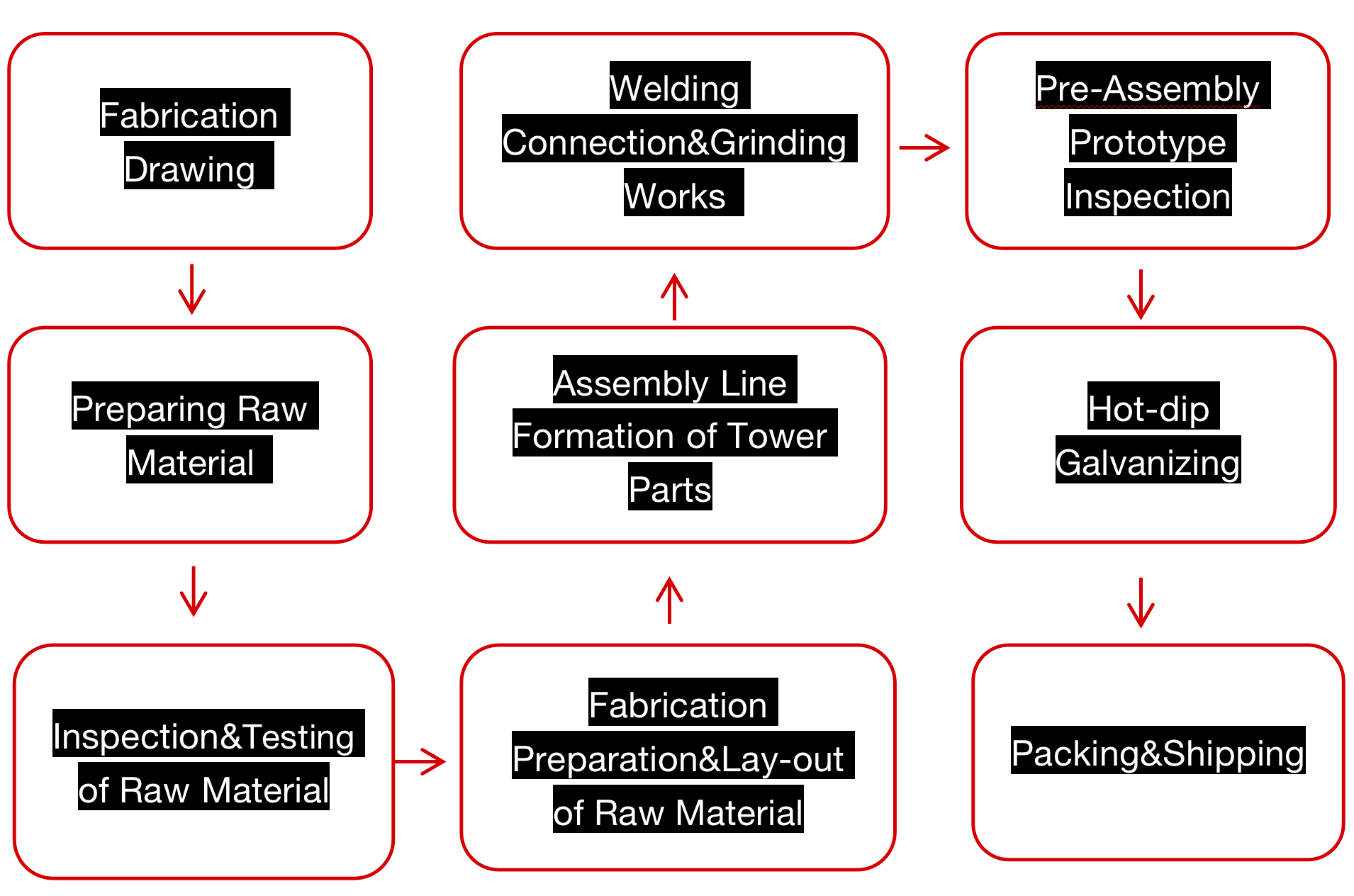

4. Quality control: Following ISO 9001 system and strictly QC inspection for raw material, trail assembly test before mass production, dimension verification, galvanization test and issuing factory report before shipment for the both quantity and quality.

We are equipped with the leading CNC angular steel production line and CNC plate processing line which is introduced, also with other 200 sets of fabrication equipment,to assure the proper manufacturing and quality of steel tower projects.