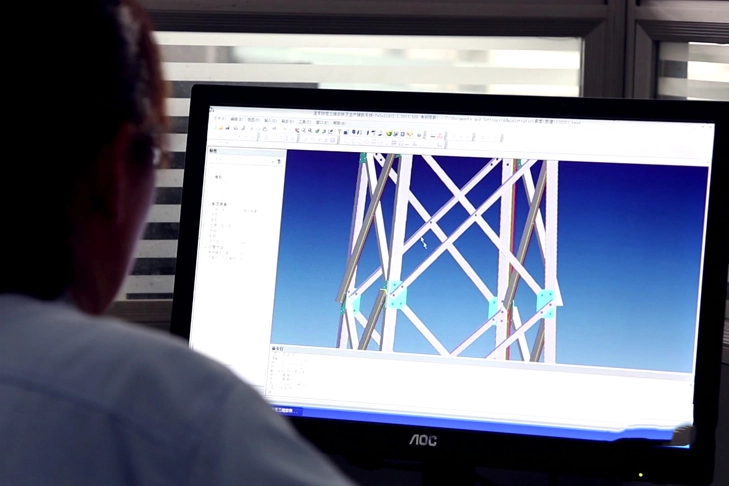

Prior to the sales process, our engineers will meticulously review any available detailed drawings to assess opportunities for optimization, including the potential for cost-effective material substitutions without compromising safety. In cases where detailed drawings are not provided, we will work closely with the client to gather essential information for the initial steel tower design, offering guidance on the preliminary outline drawing to ensure integration into the local environment. Upon receipt of specific requirements, we will commence the detailed drawing process and make revisions as per the client's new requests. Ultimately, the design drawing will be finalized through collaborative efforts, following formal confirmation from the client.

We adhere strictly to production regulations and relevant national processing standards in the fabrication of all steel structures. Prior to production, we conduct thorough lofting and assign a dedicated team to oversee the manufacturing process of each order. The team leader is responsible for supervising the entire manufacturing procedure and maintaining vigilance during critical stages such as welding and punching. Only qualified operators are permitted to proceed with important phases. Following production, trial assembly and testing are conducted to ensure the product’s integrity. Finally, a comprehensive factory report is issued prior to delivery of the goods.

Generally, for all the parts of the steel towers we will do hot-dip galvanization for anti-corrosion according to GB/T 13912-2002 (thickness of zinc coating 65/86μm) or ASTM A123/153. But if need, we can do painting or spray additionally, and clients just need to name the color RAL.

Typically, hot-dip galvanization is carried out on all components of the steel towers to provide anti-corrosive protection in accordance with GB/T 13912-2002 (with a zinc coating thickness of 65/86μm) or ASTM A123/153 standards. However, if required, we can additionally apply painting or spray coating, with clients simply specifying the RAL color of choice.

1. If clients are able to install the tower themselves but require installation tools from us, we will provide comprehensive assistance by furnishing the complete set of steel tower installation tools, along with detailed instruction sheets. Additionally, we can offer guidance and support throughout the installation process.

2. When clients require skilled installation guidance for their team, we can dispatch an expert to assist and conduct a final inspection.

3. Alternatively, our own construction team can be deployed to the site to oversee and complete the entire installation process.

1. In the event of any issues with the packaging upon receipt of the goods, we will promptly assess for damages and determine the necessary steps for resolution. Typically, backup parts are included with the delivery to mitigate any potential damage or loss. If backup parts are not available, we will provide recommendations for repair. If restoration is not feasible, the client can procure replacement parts locally or we can arrange for a resend, with any associated costs being covered by us.

2. Throughout the installation process, should the client encounter difficulties in matching the parts with the provided drawings, we are readily available to offer assistance at all times.

3. We offer comprehensive maintenance guidance for the entire operational lifespan of the steel towers.