Building telecom towers seems straightforward, right? Wrong. Overlooking key planning details leads to costly delays and structural issues. This article will guide you through the critical insights needed for success. Key insights for telecom tower construction involve meticulous site selection, robust structural design considering loads and environment, adherence to regulations, efficient logistics for materials and equipment, and stringent safety protocols throughout planning and execution. Telecom towers by our telecom tower factory are the backbone of modern communication. Getting their construction right is crucial. From our 15 years of experience at Junjiang Construction, delivering quality steel structures across the globe – from Malaysia and Singapore to Peru and Tanzania – I've learned that success hinges on understanding the complete picture, from the initial survey to the final installation. It’s not just about erecting steel; it’s about careful planning, precise execution, and navigating a complex web of factors. Let’s break down what really goes into building these essential structures. This knowledge is vital whether you're commissioning a tower or involved in the build process itself.

Wondering how a giant telecom tower actually gets built? Worried about missing a crucial stage? I'll outline the essential steps from start to finish for you. The telecom tower construction process typically includes site acquisition and surveying, detailed design and engineering, foundation construction, tower erection (assembling sections), antenna and equipment installation, and finally, testing and commissioning. ! Building a telecom tower is a multi-stage operation demanding precision. I remember a project in a remote area where skipping a detailed geotechnical survey caused foundation issues later. It taught me the hard way: follow the process diligently. Each step builds upon the last.

This phase involves finding and securing the right location (site acquisition), which needs clear line-of-sight and accessibility. Then comes the detailed site survey, including topographical mapping and soil testing (geotechnical investigation). This data feeds into the structural design and engineering phase, where engineers calculate loads (wind, ice, equipment weight) and design the tower structure and foundation accordingly. Obtaining permits and approvals from local authorities, aviation administrations, and environmental agencies is also critical here.

Foundation work begins first. This is vital for stability and depends heavily on the soil conditions identified earlier. It might involve excavation, rebar installation, and concrete pouring. Once the foundation cures, the tower erection starts. Steel sections, prefabricated based on the design, are transported to the site. Crews use cranes to lift and bolt these sections together, level by level. Precision is key to ensure the tower is perfectly vertical.

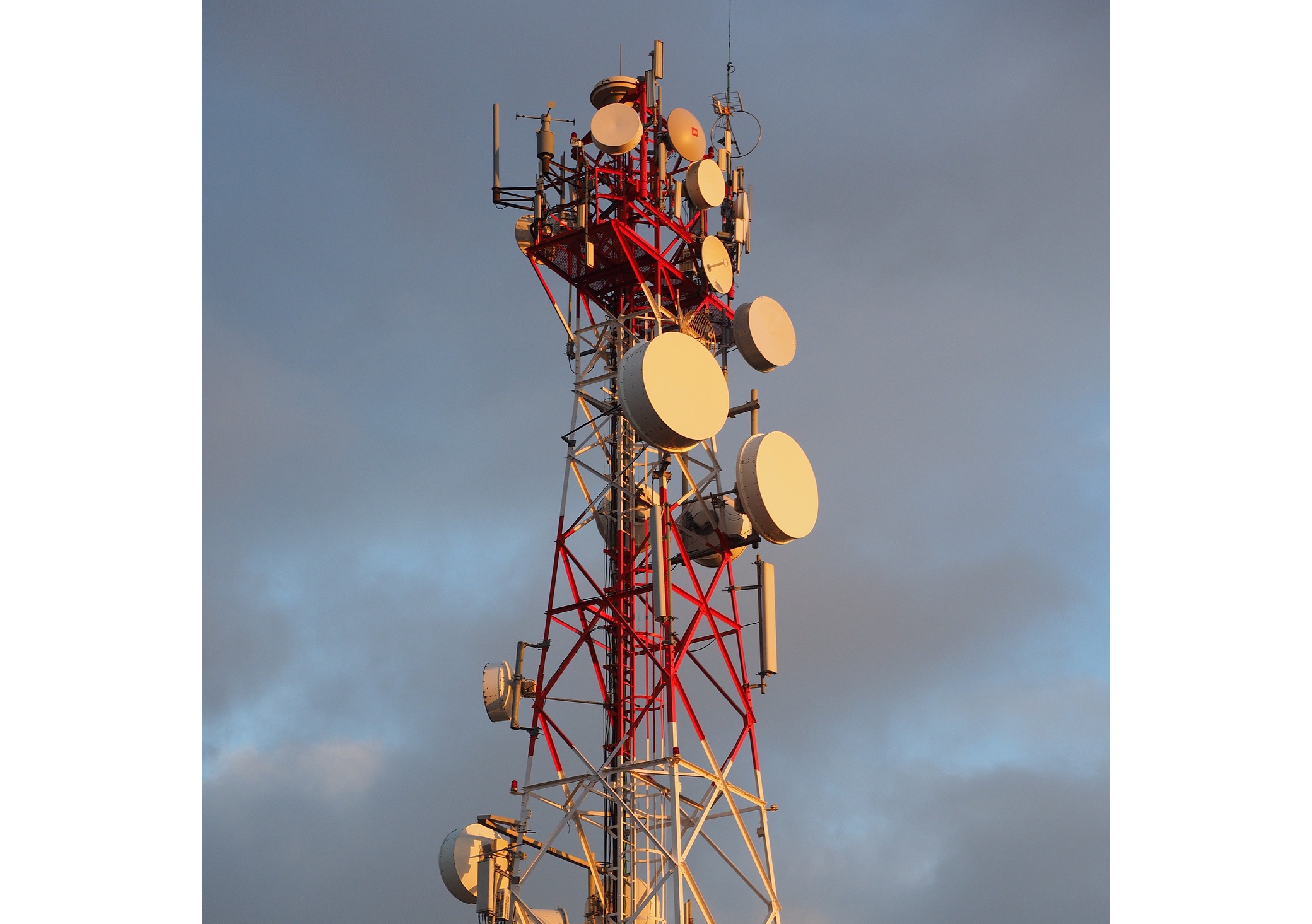

After the main structure is up, specialized crews install antennas, transmission lines, microwave dishes, and other telecom equipment according to the network provider's specifications. All cabling and grounding systems are put in place. The final step involves rigorous testing of the structure and equipment, system integration checks, and final commissioning to ensure the site is fully operational and meets all performance standards before handover.

| Stage | Key Activities | Importance |

|---|---|---|

| Pre-Construction | Site Acquisition, Surveying, Design, Permitting | Establishes feasibility and technical specs |

| Foundation | Excavation, Rebar, Concrete Pouring | Provides stability, crucial for tower life |

| Tower Erection | Section Delivery, Lifting, Bolting | Assembles the physical structure accurately |

| Equipment Install | Antennas, Lines, Dishes, Cabling, Grounding | Enables the tower's communication function |

| Testing/Commissioning | Structural Checks, System Tests, Handover | Ensures operational readiness and safety |

Following these steps systematically ensures a safe, compliant, and functional telecom tower.

Curious about what actually makes up a telecom tower? Concerned about material quality and durability? I’ll break down the essential building blocks for these structures. Telecom towers primarily use high-strength galvanized steel for the main structure (lattice sections or monopoles). Concrete is essential for foundations. Other components include bolts, fasteners, grounding systems, climbing ladders/pegs, and antenna mounting hardware.

The choice of materials directly impacts a tower's strength, lifespan, and resistance to environmental factors like corrosion and wind. In our work at Junjiang Construction, supplying steel structures internationally, we always emphasize using certified, high-grade materials. Quality components are non-negotiable for safety and long-term performance.

This is the star player. Most towers are made from galvanized steel sections. Galvanization (coating with zinc) provides crucial protection against rust and corrosion, especially important for structures exposed to the elements 24/7. The steel must meet specific strength grades (like ASTM standards) to handle the calculated loads. Towers can be:

Lattice Towers: Made of bolted or welded steel sections forming a stable, truss-like structure. Common for taller towers or heavier loads.

Monopoles: Single, often tapered, steel poles. Aesthetically preferred in some areas, usually for shorter heights.

Guyed Masts: Slender masts supported by tensioned guy wires anchored to the ground. Very height-efficient but require a larger land footprint.

Reinforced concrete is the standard for foundations. The mix design and the amount of steel reinforcement (rebar) depend on the soil conditions and the tower's weight and height. Proper curing is essential for achieving the required compressive strength.

High-strength bolts, nuts, and washers are critical for assembling lattice towers and connecting components. These must also be galvanized or made of corrosion-resistant material. The correct torque specifications must be followed during installation.

Other necessary parts include:

Climbing Facilities: Ladders, step pegs, safety climb systems for maintenance access.

Antenna Mounts: Brackets and frames designed to securely hold various types of antennas and dishes.

Grounding System: Copper wires, rods, and connectors to protect the tower and equipment from lightning strikes.

Cable Trays/Ladders: To organize and support transmission lines running up the tower. Selecting and properly installing these materials ensures the tower stands tall and functions reliably for decades.

Worried about compliance? Unsure of the safety rules needed for tower projects? I'll highlight the critical regulations and safety practices that cannot be ignored. Essential regulations cover zoning, aviation clearance (like FAA rules), environmental impact assessments, and structural codes. Key safety measures include fall protection, proper equipment handling (cranes), site security, and adherence to OSHA or equivalent standards. Cutting corners on regulations or safety is a recipe for disaster – leading to fines, project shutdowns, or worse, serious accidents. I’ve seen projects delayed significantly because permits weren't properly secured early on. Safety isn't just a priority; it's fundamental.

Navigating the regulatory landscape is a major part of planning. Key areas include:

Zoning and Land Use: Local government rules dictating where towers can be built, height restrictions, and aesthetic requirements. Public consultation might be needed.

Aviation Safety: In the US, the Federal Aviation Administration (FAA) requires notification and potential marking/lighting for towers exceeding certain heights or near airports to ensure aircraft safety. Similar bodies exist globally.

Environmental Regulations: Assessing potential impacts on wildlife, wetlands, historical sites, and complying with environmental protection laws.

Structural Codes: Adhering to national and international engineering standards (like TIA/EIA standards for towers) that define design loads, materials, and construction practices.

Safety during construction is paramount due to the heights and heavy materials involved. Critical measures include:

Fall Protection: Mandatory use of harnesses, lanyards, and certified anchor points for anyone working at height. 100% tie-off policies are common.

Training: Ensuring all crew members are trained and certified for tower climbing, rescue operations, and equipment operation (like cranes and lifts).

Site Security: Fencing off the construction zone, controlling access, and posting warning signs.

Equipment Safety: Regular inspection and maintenance of cranes, hoists, and personal protective equipment (PPE). Safe rigging and lifting plans are essential.

Emergency Planning: Having clear procedures for rescues, accidents, and severe weather events. Adherence to standards like those from OSHA (Occupational Safety and Health Administration) in the US, or similar bodies worldwide, is non-negotiable. A strong safety culture saves lives and keeps projects on track.

Facing difficult terrain or permit delays? Worried about weather impacting your tower build? I'll discuss common hurdles and how we successfully navigate them. Common challenges like difficult site access, permit delays, adverse weather, logistical issues, and skilled labor shortages can be overcome through thorough planning, proactive communication, flexible scheduling, experienced logistics management, and strong contractor relationships.

Every telecom tower project has its unique challenges. I remember one project in Tanzania where seasonal rains made site access nearly impossible for weeks. Overcoming these requires foresight and adaptability. Relying on our 15 years at Junjiang Construction, we've developed strategies.

Remote locations or difficult terrain can complicate moving equipment and materials.

Solution: Conduct thorough route surveys early. Plan for road improvements if needed. Use specialized transport (e.g., all-terrain vehicles, helicopters for very remote sites). Break down components for easier transport.

Navigating bureaucracy can be slow and frustrating.

Solution: Start the permit application process very early. Engage with authorities proactively. Employ local experts familiar with regional regulations. Have contingency time built into the schedule.

Wind, rain, snow, or extreme temperatures can halt construction, especially work at height.

Solution: Monitor weather forecasts closely. Build flexibility into the schedule to accommodate weather days. Ensure safety protocols are strictly followed during marginal conditions; stop work when unsafe.

Getting the right materials and equipment to the site on time can be complex, especially for international projects.

Solution: Use experienced logistics providers. Plan procurement and shipping well in advance. Have backup suppliers if possible. Ensure proper storage and inventory management on site. Our experience shipping to places like Japan and Peru has taught us meticulous planning is key.

Tower climbing and specialized telecom installation require trained personnel, who can be scarce in some regions.

Solution: Partner with reputable construction firms with certified crews. Invest in training programs. Plan labor needs well ahead of time.

| Challenge | Mitigation Strategy | Key Element |

|---|---|---|

| Site Access | Early surveys, road work, specialized transport | Planning |

| Permit Delays | Early application, proactive communication, local expertise | Proactiveness |

| Weather | Monitoring, flexible scheduling, strict safety adherence | Adaptability |

| Logistics | Experienced providers, advance planning, good inventory control | Management |

| Skilled Labor | Reputable partners, training, advance resource planning | Resources |

Successful telecom tower construction from professional steel tower manufacturers hinges on detailed planning, quality materials, strict adherence to regulations and safety, and overcoming challenges through experience and foresight. It demands expertise every step of the way.